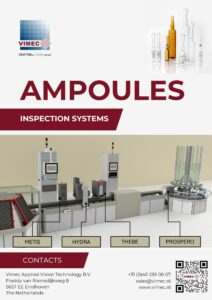

Click here to see an overview of our solutions for ampoules

In forming: Prospero

The Prospero system is mounted on the carousel/forming machine and measures the outer dimensions of ampoules. A fast and reliable inspection is performed in-line, chuck-mounted ampoules on non-indexing carousels/forming machines get measured automatically. This setup allows faster maintenance; slide the unit out, perform the required activity and slide the unit back in place again.

The information from Prospero-measurements can optionally be used to optimize the forming process. In a feedback-loop, Prospero provides information to adjust the forming process, usually this is done through real time burner-control.

Inspection-results are displayed on the screen in a graphical form, showing each measurement in a graph. In addition to that, the performance of each individual chuck and tool can be reviewed, as well as the performance over the full batch for each measurement.

Download Prospero leaflet

After oven: Thebe

After oven: Thebe

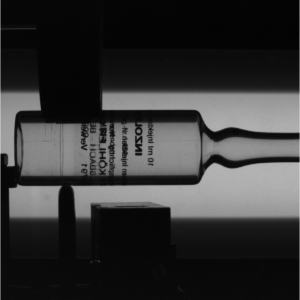

Thebe systems perform dimensional and OPC (One Point Cut) inspection of ampoules in a single inspection unit. A typical inspection unit contains area-scan camera’s and a line-scan setup for OPC inspection. The ampoule is illuminated using bright field back-light.

The area scan cameras have a perpendicular view and perform dimensional measurements. The OPC camera has an angled view and performs measurements on the OPC crack, the dot and the color rings.

For handling of the ampoules, the Thebe systems uses a Vimec Rotohandler. This handling-unit was designed to provide a high stability and more inspection-time than conventional lifting units. In the inspection position, the ampoule is rotated over 360 ⁰. The rotation speed is set, monitored and controlled by the software.

The computer, screen and main electronics are positioned in a control cabinet. This unit is usually placed next to the line to enable operators to see the physical process and User Interface at the same time.

The Thebe system uses a modular setup with modules separately listed in the software. Additional inspection functionality or inspection units (individually placed on to the line) can be added to the existing user-interface. All inspection software can be controlled through a single user-interface when required.

After oven: Metis

The Metis system performs print verification inspection. Each print is compared to a reference image, known as the golden image. Metis has a dedicated lifting mechanism and optical configuration (illumination, camera & lens) to ensure reliable and robust image-capturing in all conditions.

The best performance is achieved when the print-quality is stable. For best results, the use of non-reflective paint is advised.

As always, image capturing is important for the system-performance. Vimec achieves high-quality images of a rotating product through a high precision rotation motor and encoder. During rotation over 360 ⁰, the print is inspected. This may include inspection on letters, scale, logo’s, symbols, etc.