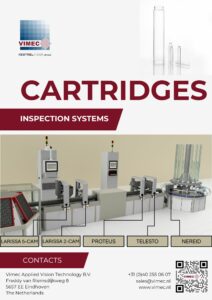

Click here to see an overview of our solutions for cartridges

NEW!

Introducing Titan: unique off-line dimensional measurement system with unmatched high accuracy

In forming: Nereid

The Nereid inspection system is mounted on the carousel / forming machine(s) and measures the outer dimensions of the shoulder, neck and lip. Measurement is performed while the product is mounted in a chuck as commonly used in hot-end circumstances. Nereid systems are available for indexing and non-indexing forming machines and always include a dedicated optical design. Vimec has designed Nereid to cope with the hot environment in a forming machine.

Inspection-results are displayed on the screen in a graphical form (each measurement in a graph). In addition to that, the performance of each individual chuck and tool can be reviewed, as well as the performance over the full batch for each measurement.

Before oven: Telesto

The specific property of Telesto is that it inspects the inner diameter of a product. Images are captured using a perpendicular view while the cartridge is lifted from the line and presented in front of a bright field illumination. During this presentation an image is taken. A full scan is performed in the measured inner diameter. A Telesto inspection is also available for the inner diameter at the back of the cartridge.

The Telesto system can be combined with other inspection systems under the same user interface. Multiple inspection modules can be added to the Graphical User Interface (GUI). Telesto uses special handling and a dedicated optical configuration to provide most accurate inspection performance.

Before oven: Proteus

The Proteus system delivers an in-line dimensional inspection of cartridges. Dimensional inspection is performed very close to the forming process, providing fast feedback for real-time controls. Proteus ensures your production-quality by responding to fluctuations. To enable inspection, the cartridge is lifted from the line using a Roto-handler and is then measured during a full rotation of over 360⁰. An optimized optical configuration is used for accurate measurements of outside dimensions. The results and performance of multiple forming machines can be observed and monitored.

After oven: Larissa

The Larissa system is used for the cosmetic inspection of cartridges. To ensure that only perfect products will be shipped to your customer, the final check is usually a cosmetic inspection.

Multiple viewing angles and optical configurations are used to provide a complete view of each cartridge. The default configuration uses a Roto-handler for handling and presenting the cartridges. Vimec designed the Roto-handler to offer high-speed handling, allowing a constant and controlled quality at higher production speeds then other known techniques. A cartridge is rotated over 360 degrees during inspection.

After oven: Atlas – Stress in Glass Inspection

Atlas systems performs inline stress detection after the Oven. It is designed to detect the presence of residual stress in the body or neck of a Cartridge.