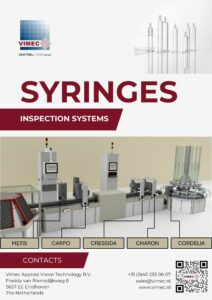

Click here to see an overview of our solutions for syringes

NEW!

Introducing Titan: unique off-line dimensional measurement system with unmatched high accuracy

In forming: Cordelia

In forming: Cordelia

The Cordelia inspection system is mounted on the carousel / forming machine(s) and measures the outer dimensions of the shoulder and conus while the product is mounted in a chuck. Cordelia systems are available for indexing forming machines.

The design includes a dedicated optical setup. Precision guided linear movement of the unit allows faster maintenance; Simply slide the unit back, perform the required activity and slide the unit in place again.

Inspection-results are displayed on the screen in a graphical form (each measurement in a graph). In addition to that, the performance of each individual chuck and tool can be reviewed, as well as the performance over the full job for each measurement.

Before oven: Charon

The Charon system inspects the inner diameter of the backside of a syringe, using a perpendicular view. Each syringe is lifted from the line and presented in front of a bright field illumination. During this presentation an image is taken. A full scan is performed in the measured inner diameter.

The Charon system can be combined with other Vimec inspection systems, including one User Interface. Charon uses special handling and a dedicated optical configuration to provide high inspection performance in challenging situations.

Before oven: Cressida

The Cressida system offers an accurate inspection of dimensional aspects of the syringe. Oftenly this includes the outer contour, including the tip and flange. The inspection can be performed far upstream, close to the forming process. This strategic point of inspection allows valuable and real-time feedback about the carousel / forming application, enabling continuous optimization of the production process. The Cressida has a modular setup, allowing additional inspection stations to be added (master/slave configuration), maintaining the same use interface.

All measurement data is collected and graphical trends, histograms and measurements data of current and historical production batches can be reviewed or provided in a reporting format. Share insights instantaneously by automatic distribution of reports to various email addresses.

After oven: Carpo

After oven: Carpo

The Carpo system performs cosmetic inspection of syringes. In order to capably detect and measure the various aspects of the syringe, Carpo integrates various viewing angles, light-sources and camera’s. Additional viewing angles are included to enhance the challenging aspects of shoulder, flange and tip area’s. Both areascan and linescan cameras are used to benefit from their synergetic effect.

Typical defects which the Carpo will detect include cracks, chips, scratches, deformation, grooves, dirt, etc. This inspection is typically performed after the oven. The system has a modular setup, allowing additional inspection stations to be added (master/slave configuration), while maintaining the same use interface.

After oven: Metis

The Metis system performs print verification inspection. Each print is compared to a reference image, known as the golden image. Metis has a dedicated lifting mechanism and optical configuration (illumination, camera & lens) to ensure reliable and robust image-capturing in all conditions. The best performance is achieved when the print-quality is stable. For best results, the use of non-reflective paint is advised.

As always, image capturing is important for the system-performance. Vimec achieves high-quality images of a rotating product through a high precision rotation motor and encoder. During rotation over 360 ⁰, the print is inspected. This may include inspection on letters, scale, logo’s, symbols, etc.

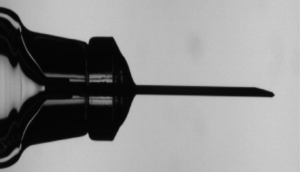

After needle bonding: Phoebe

After needle bonding: Phoebe

After the needle has been inserted to the syringe, our Phoebe system verifies the end-quality. Using different viewing angles and various cameras, Phoebe is able to measure the syringe and needle. The inspection system uses bright field illumination for all viewing angles and the product is rotated over 360° for full inspection area coverage.

A dedicated viewing angle is defined to accurately inspect the needle tip for any damages or deformations. Also, the glue height can be inspected using this system. Typical measurements performed by Phoebe include: needle angle, glue angle and height, glue presence on cone and needle, hook and total length.